AGM products are built on core technologies in the area of Optical MEMS (Micro Electro Mechanical Systems), and provide the core technology enabling Optical MEMS Components, such as Tunable filter, Variable Optical Attenuator, and 2D MEMS Mirror for 1xN Optical switches. On their path to market, AGM products depend on a number of other critical technologies that allow for fabrication of these devices and ensure their quality and reliability in the field. Semiconductor Wafer Processing is one of the supporting technologies that enables the integration of Optical MEMS Technology, while Automated Testing allows for the products to be verified in an accurate and timely manner before deployment.

Optical Components have traditionally been divided into (i) Active Components, such as Lasers, Detectors, Modulators, Transceivers, etc; and (ii) Passive Components, such as Filters, Couplers, Splitters, Isolators, etc. Recently, a modification has been proposed to this categorization scheme that would introduce a new class of Optical Components known as Dynamic Components. Dynamic Components are inherently passive but have the added functionality of changing a physical parameter of the light or reconfiguring its optical path in real time. This class of components includes: the Variable Optical Attenuator (VOA), the Tunable filter, the 1xN Optical Switch, the Wavelength Selective Switch (WSS), Optical Cross-connect Switches (OCS), the Dynamic Dispersion Compensation, etc. The preferred technology for enabling Dynamic Components is Optical MEMS (Micro Electro Mechanical Systems). 2D MEMS Mirror

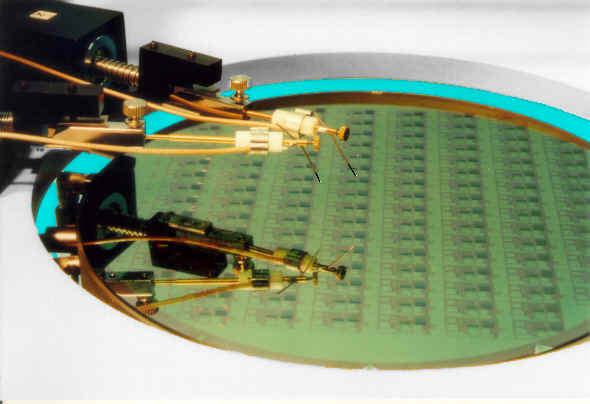

AGM’s core products, including the Electrostatic Variable Optical Attenuator (ESVOA) chip and the 2D MEMS Mirror chip, are built upon basic Optical MEMS technology (micromirror with comb drive actuation). Along with the Optical MEMS technology that forms the core of AGM products, a number of other technologies play crucial roles in bringing AGM products to market and making sure they are effective and reliable in the field. Semiconductor Wafer Processing is one of these technologies.

In the realm of testing and verification, a number of interrelated technologies come together to enable reliable and efficient device testing at AGM. These include wafer probers, optomechanical fixtures, advanced optical measurement instruments, electronic and optical hardware, and customized test software using advanced algorithms. AGM has developed Automated Test Systems for testing Optical MEMS chips with high precision and high throughput.